As if the grid was not challenged enough by its aging infrastructure and the rising power demand, the pool of skilled workers is shrinking and hard to replace.

This workforce shortage has major consequences. It threatens the ability to continuously supply power, with all the downstream impacts on consumers’ well-being, productivity, or even health. It also threatens lineworkers’ safety.

Lineworkers are essential to maintaining the grid’s continued operations. When they cannot, outages, both short and long, are multiplying. To keep the power on even with an insufficient workforce, lineworkers are taking more risks, endangering their health, or even putting their life at risk.

Technological advances able to mitigate those problems are emerging not a moment too soon.

The Growing Skills Gap in Grid Maintenance

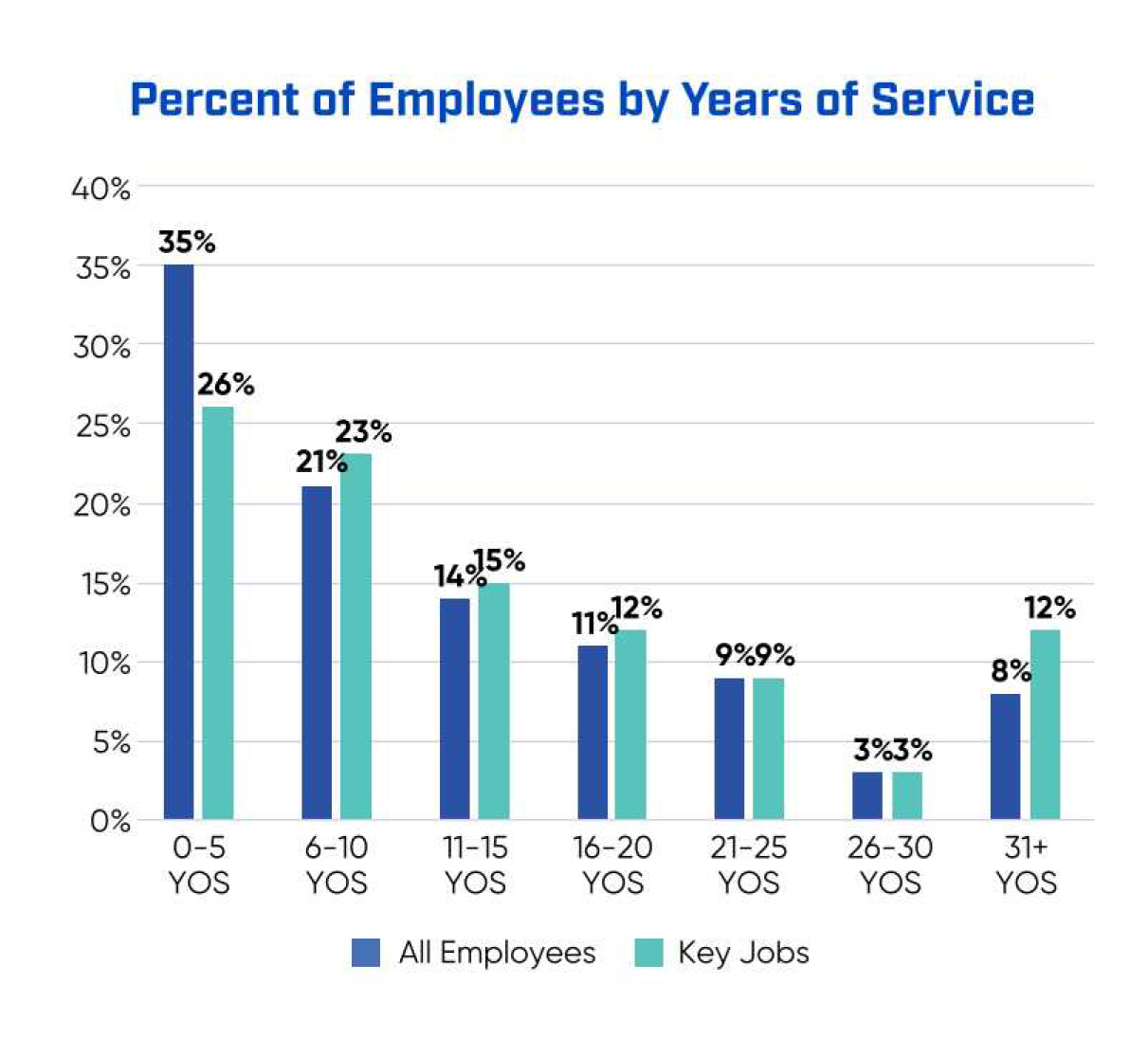

Already today, the number of qualified grid maintenance workers available to join the workforce is barely sufficient. These jobs can’t be transferred or outsourced and have to be fulfilled locally. That is only the tip of the iceberg, though. The U.S. Department of Labor predicts a wave of retirements of almost half the existing workforce in the coming decade. Europe is not faring better.

Source: 2023 Energy Workforce Survey, the Center for Energy Workforce Development (CEWD)

The knowledge gap is double. Retirees’ decades of valuable technical knowledge related to legacy infrastructure are difficult to replicate but crucial to recruits’ training. Recruits also need to acquire new skills adapted to the grid’s increased complexity.

The integration of less expensive renewable energy sources into existing grids worldwide requires fine-tuning the ability to absorb asynchronous power sources into a grid designed for stable power output. Renewables’ production is directly dependent on the weather conditions, and, as such, the same source’s production can slow to a crawl on a cloudy or windless day or break all records when the sun shines high in the sky or the wind blows just the right way.

Orchestrating the dual stable and intermittent input requires a comprehensive understanding of the existing decades-old grid infrastructure and an equally thorough understanding of the smart grid’s upcoming options.

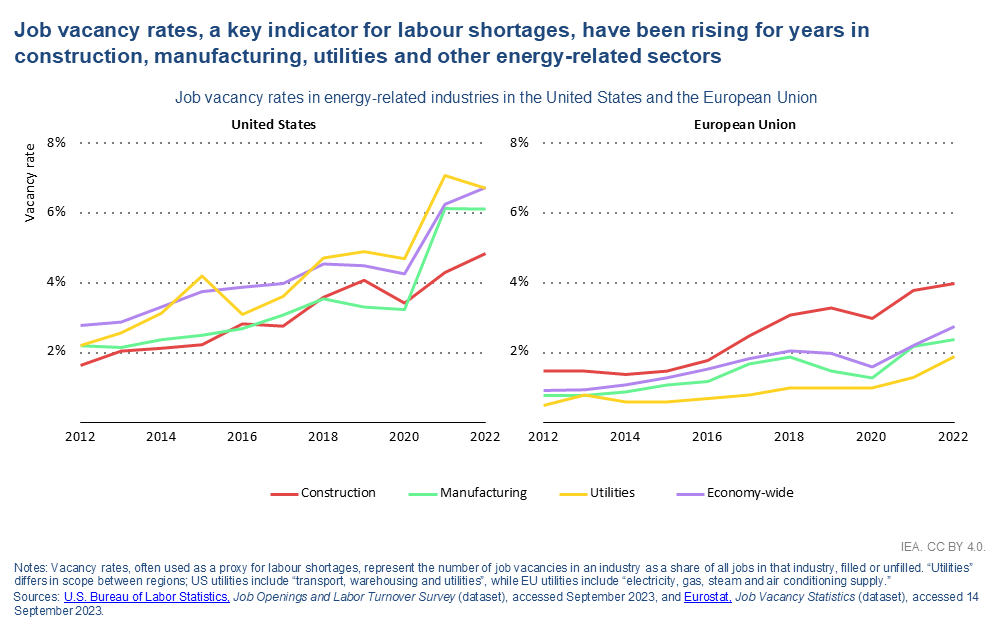

Source: IEA World Energy Employment (WEE) report, 2023

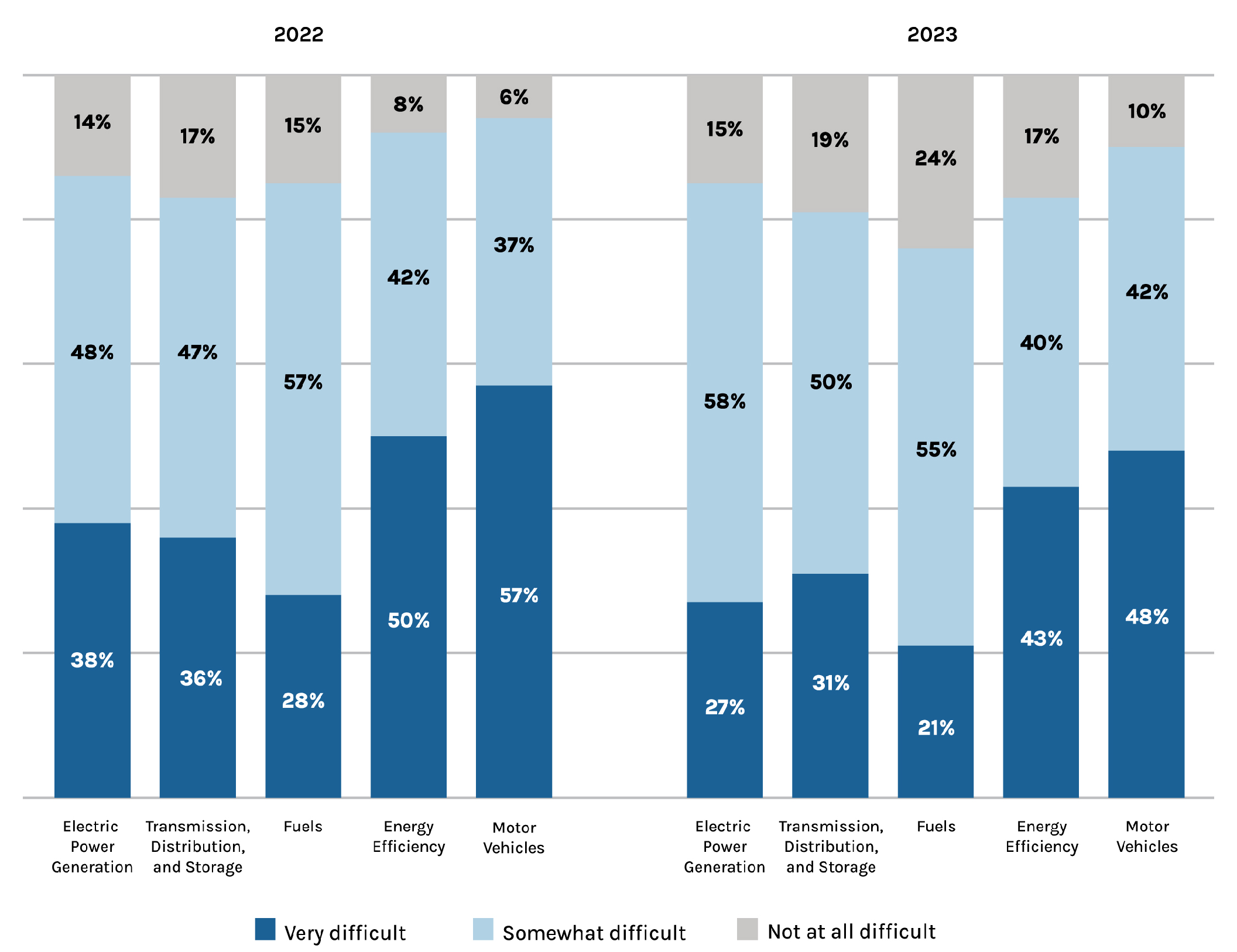

Although the hiring situation shows little progress, hiring workers in the electricity transmission, distribution, and storage fields remains disproportionately tilted towards somewhat or very difficult. These are workers essential to keeping the grid in working order and efficiently balancing the load.

Skill shortage effect on power supply

The shortage of skilled lineworkers directly threatens power supply continuity and increases the odds of longer and more frequent outages. Lineworkers maintain and repair transmission lines. If there are too few of them, they cannot physically attend to all the line issues in time to prevent outages. And they need more time to perform the repairs, potentially days or even weeks. This extended repair time is made even worse when experienced workers leave, as less experienced lineworkers need to find out how to address uncommon issues on their own.

All the while, consumers have to manage without power. Aside from the discomfort of a lack of power, the economic cost is astronomical. The outage total cost to residential and commercial customers in the United States is predicted to reach between $1.5 and $3.5 trillion by the year 2050.

With those risks in mind, still, the U.S. Department of Energy (DOE) tracking energy employment finds that hiring transmission workers is difficult, as seen in its reports.

Source: U.S. Department of Energy – Energy & Employment 2024 Report

Lineworkers’ skill shortage also directly affects their health and safety.

Risks to the Workforce During Severe Weather and High-Risk Conditions

High-voltage transmission lines are, by definition, a high-risk work environment. The risk of lethal electrocution from live lines is ever-present, even in the best work conditions. Transmission line repair and maintenance often require lineworkers to perform in difficult work environments such as tower lines built in mountainous or swampy terrain.

Bad weather also contributes to increasing the risk to lineworkers. Heat waves carry the risks of heat strokes and dehydration, and winter cold can cause frostbite and hypothermia. Extreme weather events make those even worse and seem to be more and more frequent. Storms increase the risks of flooding, lightning strikes, falling debris, and slippage.

The intense pressure to keep the power on or restore it as fast as possible adds a mental toll on the lineworker and increases the odds that they will take more risks, and extracts a heavy physical toll that increases fatigue and can impact lineworkers’ ability to focus on the task at hand.

As a result, between 2021 and 2023, the fatality rate for electrical power-line installers and repairers is 23.7 per 100,000, compared to an average of 3.7 per 100,000 for the entire working population. Close to 2000 per 100,000 experience non-fatal injuries leading to sick days, further reducing the number of available workers.

Can technology optimize skilled workers’ productivity and reduce risks?

When talking about transmission lines, the extent of damage increases maintenance costs, the odds and duration of outages, and the risks to skilled workers. Logically, it follows that technologies that enable early identification and localization of damage to the line directly improve all three factors.

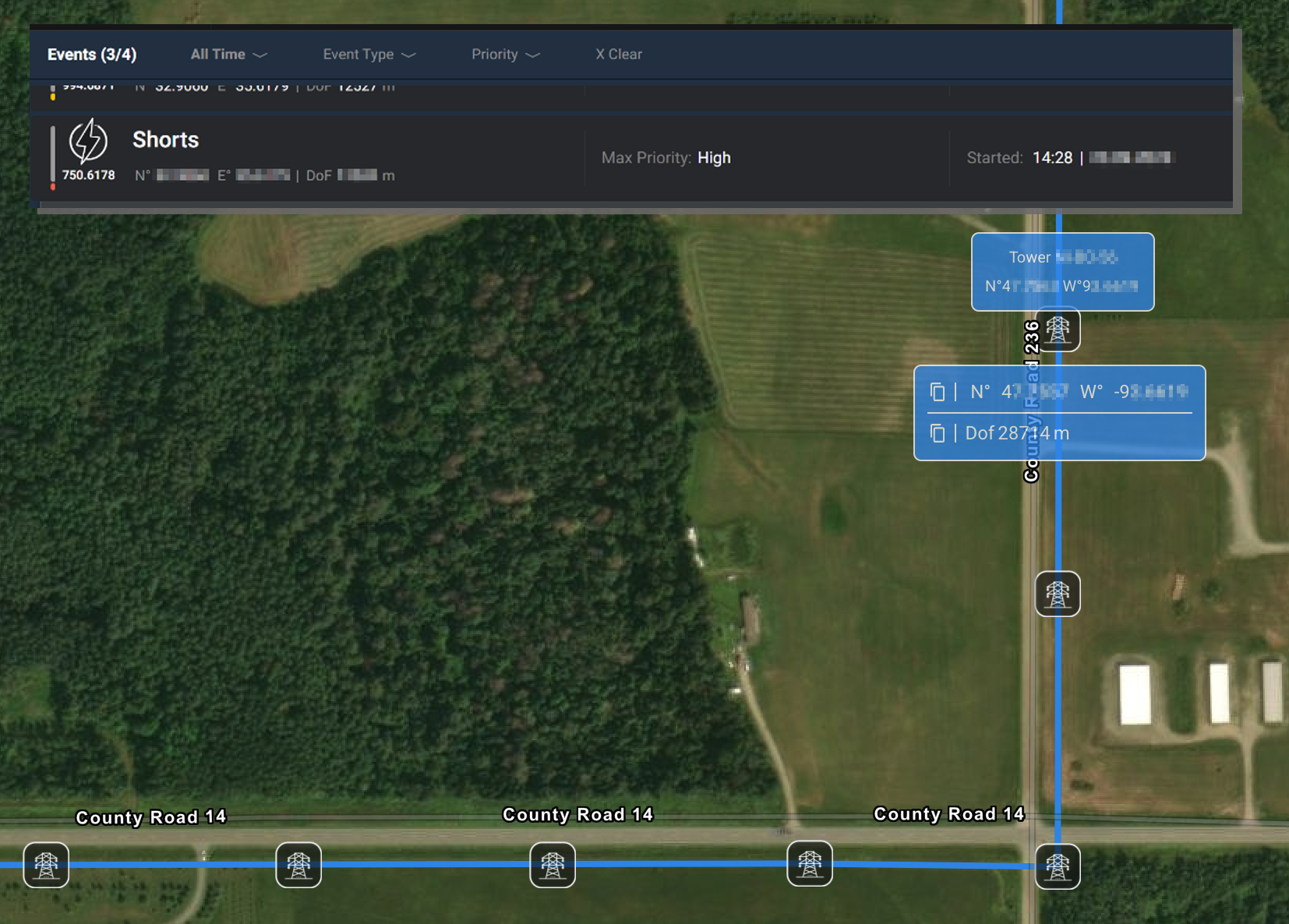

Fiber optic cable monitoring is the most advanced such technology currently available. It is also highly cost-effective. Technically, it leverages existing OPGW cables by converting a single one of its tens or more fibers into an array of very sensitive sensors. The optical fiber based monitoring detects events and pinpoints their locations to specific towers in real-time. Events such as short circuits, partial discharge, line icing, galloping lines, wind and temperature variation, and more are detected early and analyzed with advanced algorithms.

An example can be seen here with an alert for a short circuit. The system displays the Tower ID and exact location, with GPS coordinates that enable a quick truck roll to inspect and address potential damage. This pinpoint accuracy and immediate alert help lineworkers operate efficiently, without the need to scan large areas, and provide the advantage of knowing in advance the nature of the event, allowing them to adjust accordingly.

Source: PrismaPower screenshot of a customer-monitored line

Grid Predictive analysis further refines the result and diagnoses the problem. Lineworkers can then be sent to the exact location of the issue at an early stage and fix the problem before it leads to costly repairs.

The benefits of pinpointing the exact location of an issue save a lot of time otherwise spent on locating the issue across multiple spans. The benefits of early diagnostics are triple. They prevent damage escalation, they enable line strengthening before emergency interventions, which, in turn, limit the occurrence where lineworkers have to work in extreme conditions, and they reduce the number of outages.

Prisma Photonics pioneers advanced monitoring solutions and grid predictive analytics.

Prisma Circuit and PrismaClimate take the detailed data collected on the grid to detect and classify events, pinpointing them down to tower locations in real-time.

Learn more about how Prisma Photonics can help Utility teams maintain accuracy & efficiency by leveraging advanced monitoring solutions for their grid – Read all about it!